SIECO ENGINEERS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SIECO ENGINEERS P.LTD.

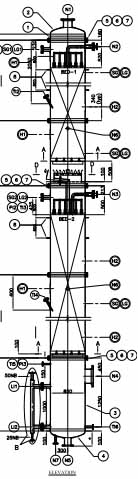

Column And Boom Manipulator

SIECO can produce with a wide capacity range from 1.5 mtrs to 6.0 mtrs (60" to 236") strokes. The Column and Boom Manipulators can be used on a wide variety of parts and part shapes.

Sieco's standard column and boom manipulators have the following specifications:

Boom drive that comprise Heavy-Duty Linear Ways and Precision Ball Screw of various sizes and Larger Rack and Pinion Drive, Servo Motor with adjustable speed

Positioner And Table Rotator

Positioner

Welding Positioner consists of worktable rotation unit and tilting unit. Through worktable elevation, the work piece fixed on the worktable can be placed to ideal position for welding and assembly by the worktable tilting and rotating. To achieve satisfactory welding speed, working table rotating is controlled invariably and continuously with inverter. Welding Positioners align the job to the best position for down hand welding for non circular jobs or for rotating circular jobs.

Seam Welders

Seam welding is resistance welding or roller welding process for joining metal sheets / seam joints between two rotating electrode wheels performed using electrical current which is passed through a lid and container. As the metal heats up, the lid is completely joined to the body of the container. Seam Welding is high speed and clean process, which is used when continuous tight weld is required. Seam Welding is mainly used on the seams of tubes and pipes for its ease and accuracy. Seam welding is used to create larger flat-stock parts, join relatively long components, and create cylinders, cones etc.

Cnc Plasma Cutting Solution

ULTRA-CUT 300 High Precision Plasma Cutting System

Quality

Excellent Dross-free Cuts Using Oxygen (O2) Plasma on Mild Steel up to 1 ¼" (35mm)

Unmatched Cut Quality on Non-ferrous Materials to 1 ¼" (32mm) with Ar-H2/N2 or up to 1" Using our Unique Water Mist Secondary (WMS) System

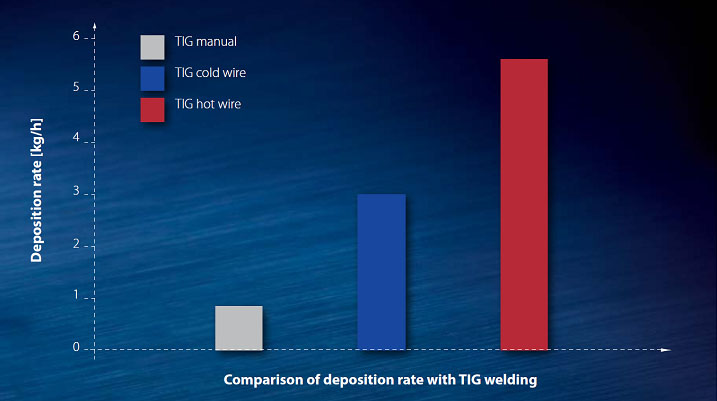

Hot Wire And Cold Wire Welding Process Gtaw And Paw

Description / Specification of Hot Wire And Cold Wire Welding Process Gtaw And Paw

We are involved in offering a wide range of Hot Wire And Cold Wire Welding Process Gtaw And Paw to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Hot Wire And Cold Wire Welding Process Gtaw And Paw. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.